- Frymaster Parts Guide - December 31, 2021

- Best Vulcan Fryer Guide For The Commercial Place - November 26, 2021

- Robot Coupe Food Processor Model Guide - November 16, 2021

Blast chillers are commercial refrigerators that use cold air to quickly cool food, drinks, and other substances. Originally invented in 1995, they have evolved since then into a staple of commercial kitchens around the world. Today, the best commercial blast chiller options are best used in restaurants, grocery stores, and convenience stores to keep fresh produce from spoiling too quickly.

Blast chillers are great for when you need to be able to serve meals at a moment’s notice, or if your establishment is open late and needs the ability to store foods overnight. They can also help prevent foodborne illnesses by making sure that foods stay at safe temperatures before being served.

This blog post will cover what blast chillers are used for, what to look for before buying one, and some frequently asked questions so you can make an informed decision on which best suits your needs.

What Are Blast Chillers?

Blast chillers are machines that quickly cool large amounts of food to keep it at safe temperatures before being served or stored overnight. Blast chillers can also help prevent illness caused by bad bacteria in food (such as food poisoning) by ensuring that foods stay at a safe temperature when being served or stored.

The History of Blast Chillers

Blast chillers and blast freezers were originally manufactured in 1995, and have become an important staple of the food industry. They were designed to quickly cool cooked food down and quickly get it out of the danger zone so that harmful bacteria cannot grow. This reduces your risk of getting sick and also helps extend the shelf life of products.

The idea for blast chillers is based on the refrigerator – many caterers see these two machines as cousins. Before the invention of fridges, people would have to go to great lengths in order to keep their food fresh. They would soak food in brine, salt cure foods, or use ice houses to keep things edible.

It was not until 1842, with the invention of the refrigerator, albeit in a much simpler form than what we have today, that these earlier preservation methods ceased to be used.

At the beginning of the twentieth century, people began to discover that blowing cold air over food was a highly effective way of quickly chilling it. So, designers and inventors took that basic concept and created a way to speed up the process. The eventual aim was to chill the food to a safe temperature as quickly as possible.

From there, the idea took hold, and blast chilling became an essential part of the commercial food industry.

What Does a Blast Chiller Do?

Blast chillers and blast freezers are perfect for any businesses aiming to comply with the FSA guidelines and HACCP legislation, as they can decrease food temperatures through the danger zone – 8˚C/46˚F and 68˚C/154˚F – safely.

Not only does this reduce bacterial growth but it also helps food stay fresh for prolonged storage, cuts down on food waste, and lets you make advanced preparations before busy services.

How Does a Blast Chiller Work?

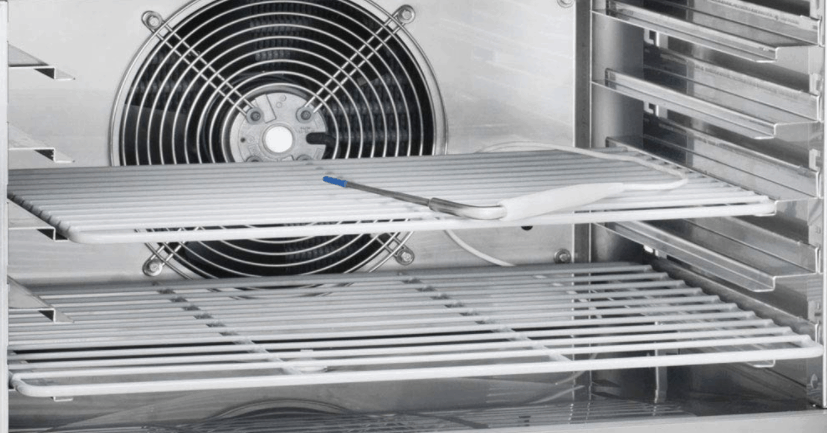

From a scientific perspective, blast chillers promote a rapid freezing process, creating small frozen crystals inside the food. All blast chillers work in the same way: they pass a constant flow of chilled air over the food, which speeds up the cooling process.

To achieve this, blast chillers use powerful compressors to rapidly push the internal temperature inside the unit down. The power of the compressor puts out a blast of cold which is then circulated through a fast-acting fan. The combination of these two components is what cools down food so rapidly.

What Are The Different Types of Blast Chiller?

Blast chillers can be broken down into two different categories: commercial and retail. Commercial blast chillers are best suited for large-scale businesses, whereas retail ones are best used in supermarkets or corner shops.

However, within these categories, there are a few different types of chillers. Lets’s take a look at this in more detail:

Countertop blast chillers

Countertop blast chillers are best used in commercial kitchens, and they’re best suited for smaller-scale businesses. They come with a convenient countertop design, which means that you don’t need to find room on the floor or fit it underneath your kitchen cupboards. These chillers are designed to work at the countertop level so that staff can easily access the machine’s controls from their standing position.

Walk-in blast chillers

Walk-in blast chillers are best suited for constant, busy restaurant use. They have a self-contained design that is great for catering areas with large volumes of customers. These machines work best when you’re looking to store or cool down large amounts of food quickly, but they do require much more space than the other types on this list.

Freestanding blast chillers

Freestanding blast chillers are best suited for smaller, independent businesses or restaurants. They’re best used in commercial kitchens with limited to large space that can’t accommodate a walk-in chiller machine. Similar to free-standing fridges and freezers, they come in a variety of different sizes and one-door and two-door models. These machines come with an excellent design and work to provide business owners the best value without compromising on quality.

Under-counter blast chiller

Under-counter blast chillers come in a range of different sizes, but they’re best suited for commercial kitchens with limited space or those who want to extend their workspaces. These machines are designed to be installed under the counter, and this compact design is best matched with smaller catering businesses. They double up as a worktop and a blast chiller, so it’s best to buy one of these if you don’t have the space for a separate countertop machine.

Portable blast chiller

Portable blast chillers are best suited for catering and event professionals. They’re great for using in the back of vans or trucks as they require no installation, making them perfect for those on-the-go events where you don’t want to be messing around with a lot of heavy equipment. These chillers function just like any other commercial machine, and they’re best matched with a business that needs to move around on location.

The Benefits of Blast Chilling

Blast chillers offer a range of different benefits to business owners, for example:

- Improved food safety – Blast chiller technology ensures food is kept at the safest temperature and therefore stays at optimum freshness for longer.

- Reduced energy usage – The best blast chillers will save you money on your monthly utility bills due to their fast cooling process. They’re also best suited if you have an inconsistent electricity supply as they won’t need constant power input in order to work properly.

- Enhanced quality control – With bulk storage capabilities, these machines can be used by larger businesses to maintain strict standards all year round without compromising consistency in taste and texture. This means that even large companies like supermarkets can benefit from purchasing a blast chiller.

- Reduced food waste – Blast chillers can best be used to optimize the use of raw ingredients, meaning that you’ll end up cutting down on wastage and using all your stocks more efficiently.

The range of benefits offered by these machines means they’re best suited for larger businesses with higher volumes of customers or chefs who want to maintain consistent quality across their products throughout the year.

What to Look For in a Commercial Blast Chiller

There are a few things that you’ll need to consider before purchasing a commercial blast chiller for your business:

The best for your business

Before investing in one of these machines, it’s important to think about what best suits the needs and requirements of your business. The best commercial blast chillers are best suited for different types of food storage and preparation, so it’s important to consider your needs before making a purchase.

How much space is available?

Blast chillers require more room than standard refrigerators or freezers because they come with larger cooling shelves. If you don’t have enough floor space available then, you could consider an under-counter unit or a countertop chiller.

Storage mode

Some units feature a storage mode. This means that, once the food has reached the desired temperature, the machine will switch to ‘storage mode’ and hold the food at that temperature for you. This is great for catering professionals who rely on bulk storage or preparation for a busy service.

Blast chilling programs

Blast chillers will usually have two cycles, a ‘soft chill’ and ‘hard chill’.

For salads, fruit, and other delicate foods with high water content, a soft chill is best. Incorporating a soft blast chill cycle on these types of food prevents dehydration and preserves the integrity of the ingredients.

In comparison, hard chill works well with most other foodstuffs. It’s the standard cycle used when blast chilling large quantities of food in bulk. There is sometimes also a hard chill max program which is best suited to food with a high quantity of fat.

You might also get a pre-chill function with some blast chillers. This ensures the cabinet is at the optimum temperature before starting to cool, improving the overall performance, efficiency, and quality of the results.

Finally, on blast freezers, a shock freeze program will bring temperatures plummeting below freezing within a recommended time frame.

Cooling and defrosting methods

Blast chillers usually rely on fan-assisted cooling methods to simultaneously and consistently circulate cold air for rapid chilling and freezing. The differences in brands, despite having the same regulatory requirements, comes down to their power. Some fans have a much more powerful motor and are capable of producing quicker results, even from higher temperatures.

Gastronorm compatibility

If you’re looking for a blast chiller that best suits catering purposes, then it’s important to consider how many gastronorms your unit is compatible with. This will make the best impact on the speed and capacity of production cycles and mean that users can simply transfer a tray rather straight into the chiller, instead of moving individual items. Some blast chiller models even come with clever roll-in gastronorm options, which make moving trays even easier.

The amount of shelves that a commercial blast chiller can hold also varies, with larger cabinets allowing for more shelves. The number of levels in a commercial chilling or freezing machine will typically be between three and fifteen, however, roll-in models may have more.

Power supply

You’ll find commercial blast chillers with a variety of power sources, including low voltage plug-in models. This means that you can best use the model for your needs and best suit it to where you’re looking to place it. In addition, the larger a blast chiller’s size and capacity is, the more power it will require to run effectively.

Features

Blast chillers are best known for quick and constant blast chilling processes. They come with large cooling shelves that measure between ten to thirty inches in depth, depending on the size of your machine. However, many will have additional features that you may want to consider before making a large purchase such as this.

A few of the features that you may find in your potential new chiller are:

- Touch control panels

- Advanced hold or storage modes

- Automatic Surface Protection – which prevents frost burn or wind chill damage to food

- The ability to record temperatures for you

- Digital memory settings

- Removable door gaskets

- High or low temperature alarms

- Wheels for easy maneuverability

Ease of cleaning

You’ll find that the best commercial blast chillers are designed to be easy to clean. Blast chillers with removable shelves and blast chillers made from materials like stainless steel that can be easily wiped down are simple and easy to clean.

Efficiency

When it comes to energy usage, it’s best to decide whether your commercial blast chiller will be used in a high or low traffic area. If you need something that can handle higher volumes of produce, then you’ll want an upright model with more shelves and a powerful fan motor.

This is because it has a larger cooling capacity which means less time spent waiting for your food to cool and be ready for consumption.

Manufacturer and price

Lastly, it’s important not to forget about the manufacturer and the price. There are a number of options available on the market, from commercial blast chillers that can handle large volumes of product types such as meat and fish, all the way down to models with smaller capacities for buffet-style catering.

Blast Chillers come in a range of sizes and prices so it pays to do your research before investing in a commercial chiller.

The Differences Between a Blast Chiller and a Freezer

The scientific process of blast chilling involves the rapid freezing of food. The expression “blast chill” is derived from this process, because it refers to a very sudden cool-down in temperature. However, it’s quite different from common freezing.

When food is stored in a domestic freezer, large crystals of ice form inside it. In contrast, a blast chiller uses a rapid freezing process to chill food, creating much smaller ice crystals. The size of the frozen crystals which form can have a drastic effect on the food once it is thawed. Larger crystals have the tendency to rupture cells in food, which can deteriorate flavor and texture. Smaller crystals thaw more slowly, preserving the taste and texture of food.

Furthermore, airflow in standard refrigerators and freezers is often stagnant, which poses a problem for food products that are stacked on top of each other. The system relies on cooling not just the food, but also the stagnant air. This is what makes it a challenge to chill food in a domestic setting and the reason blast chillers were invented – to reduce the time taken to chill foods.

In blast chillers, there is much more space between the trays than traditional chillers, meaning air can circulate, and food can be kept cooler. Most significantly, the cold air being pumped is also continuous rather than stagnant and warming up.

Some blast chillers also come with changeable shelving which means you can tailor the space provided by moving the shelving higher or lower. This helps to suit each individual piece of food that you can chill.

Advantages of a Blast Chiller

- They dramatically decrease bacteria growth – commercial blast chillers slow down the growth of bacteria in food by reducing its exposure to the temperature danger zone.

- The best commercial blast chillers reduce spoilage rates – blast chillers are powerful and fast. They can keep your products at a safe temperature for longer periods than other methods such as freezers or refrigerators. This means that they can not only reduce bacteria growth but also decrease spoilage rates.

- They have a long lifespan – life expectancy is higher with a blast chiller because of its high-quality design and materials. The best commercial blast chillers last for well over 10 years, in contrast to some fridges which often wear out after just a few.

- They are best for commercial use – best commercial blast chillers are best suited to high-volume food services such as buffets, hotels, and restaurants because they can keep your products at a safe temperature for longer periods of time than other methods such as freezers or refrigerators.

- Maintain moisture in food – blast chillers maintain moisture in food. This can be an effective way to reduce water loss and quality changes that often happen during conventional freezing methods.

- Locks in food freshness – best commercial blast chillers are best for preserving the freshness of food. They hold back spoilage and maintain moisture in your food.

- Delicate food is protected – foods such as pasta, salads, and souffles are protected from damage caused by freezing when a blast chiller is used.

- Streamlines food prep – blast chillers can also streamline food prep, allowing you to prep large batches of food at once without worrying about it going bad. This can save both time and money.

- Rapidly cool down drinks – blast chillers can rapidly cool down drinks as well as food, meaning wine that’s been stored at room temperature can be cooled to quickly serve to customers.

Disadvantages of a Blast Chiller

- Not suitable for domestic use – commercial blast chillers are only suited to high-volume food services such as buffets, hotels, and restaurants and are not suitable for home use.

- They take up a lot of space – commercial blast chillers can take up a lot of space, and are best suited to kitchens with large storage areas.

- They are expensive – blast chillers require high-quality materials and design which means they’re often more expensive than other models.

- They use more energy – the chilling process takes more energy than other methods, such as freezers or refrigerators, so they can also be more expensive to run long term.

Safety Tips of a Blast Chiller

- Only fill to capacity – blast chillers should not be filled more than their capacity. This can cause the temperature to rise and lead to spoilage or bacterial growth, which is best avoided.

- Keep it clean – even though commercial blast chillers are clean environments where bacteria shouldn’t grow, that doesn’t mean nothing will ever get spilled inside them. They should be regularly cleaned and checked for any wear or damage that could lead to contamination of food.

- Regularly check the temperatures – as with most kitchen cooling equipment, blast chillers should be monitored regularly to ensure they are at the best temperature. This is best done by checking with a thermometer or a kitchen temperature probe.

- Regularly rotate food – Make it a habit to move older food to the front of your chiller before putting in new food. This simple method of stock rotation makes sure that older food isn’t left in the chiller.

Our Top Blast Chiller Recommendations

Polar G-Series Countertop Blast Chiller 8/5kg

The Polar G-Series is a powerful and reliable blast chiller for use in the commercial kitchen. Designed to help you comply with food safety regulations, it can quickly cool your hot food supplies from +70°C to +3°C within 90 minutes. It can also freeze up to 5kg of hot food from +70°C to -18°C in just 240 minutes.

It features digital controls for easy use and an insulated door designed to maximize thermal efficiency. Cleaning and maintenance are made easy, thanks to commercial-grade stainless steel construction. This is ideal for hospitality businesses with limited storage space.

Pros

- Can both chill and freeze hot food

- Easy to clean design

- Digital controls

- Built-in food probe

Cons

- Countertop design may be too small for larger kitchens

Gram 60kg Roll-in Blast Chiller KPS 60

The Gram KPS 60 Blast Chiller, capable of cooling up to 60 kilos of food in 90 minutes, preserves meals and allows you ample time during peak periods. One of the best features of this blast chiller is that it includes an 18 gastronorm tray trolley for moving food from cooking to cooling.

It also includes an automatic temperature control which allows for increased monitoring of the chilling process. Lastly, the high-quality 304 stainless steel interior & exterior make this machine incredibly easy to clean, durable, and likely to last you for years to come.

Pros

- Can cool 60 kilos of food in 90 minutes

- Includes an 18 gastronorm tray trolley

- Automatic temperature controls

Cons

- Requires a connection to an external drain

Foster 52Kg/26Kg Blast Chiller/Freezer Cabinet BCT52-26 17/173

The Foster BCT52 is constructed from durable and sturdy stainless steel and offers a smart solution for safe, fast commercial blast chilling. Its whopping 52kg capacity is suitable for use in restaurants, takeaways, schools, and other catering establishments.

The chiller can decreases the temperature of food from 70 degrees Celsius to 3 degrees in just 90 minutes. It’s also very user-friendly. An intuitive touch screen enables detailed monitoring of the foods inside each individual cycle. Foster’s blast chiller is designed to maximize food safety in food processors of all sizes.

Pros

- Huge 52kg capacity

- Sturdy, stainless steel construction

- Intuitive easy Blast Chiller Touchpad

- Can reduce food from +70C to +3C in just 90 minutes

Cons

- Expensive

Polar U-Series Blast Chiller with Touchscreen Controller 18/14kg

This U-Series blast chiller from Polar is designed for quick and effective food cooling. A food probe is built-in to the unit and helps you monitor the cooling process, ensuring that produce reaches your desired temperature. It is not only innovative, but it also has an LCD touch screen controller that allows for simple and effective programming: users can store their own ‘recipes’ and select from pre-set cycles based on what they are chilling.

Made from durable stainless steel on the inside and out, this blast chiller is easy to clean and built to last. The locking casters allow for easy movement and mobility, which will come in handy when needing to clean or do utilities on the machine.

These powerful units are built to commercial standards and have an integrated cooling system that will help you reduce food waste while also preserving flavor.

Pros

- Built-in temperature probe

- Handy touch screen

- Durable stainless steel construction

- Programmable to make usage even easier

Cons

- A little pricey

- Might be too small for large kitchens

FAQs

Question: What is the use of blast chiller?

Answer: A blast chiller is used for quick food cooling. It is best for chilling food from 70+ degrees Celsius to as low as -18 degrees, in a very short space of time. They are commonly used by restaurants and other food establishments for preserving food and saving on prep time.

Question: What do I look for before buying a commercial blast chiller?

Answer: You should make sure that the machine has enough capacity to handle your needs, whether it be holding 15 gastronorm trays or 120 liters of space. You should also check that the chiller includes the best features for your needs, like touch screens and built-in food probes.

Question: What is the difference between a blast chiller and a freezer?

Answer: A freezer will freeze foods at -18C (-0.04F) while preserving them indefinitely. A commercial blast chiller, on the other hand, can cool below 0 degrees Celsius in a matter of minutes.

Question: What are the best commercial blast chillers?

Answer: This largely depends on the space you have available and your catering needs, but there are some great options from brands like Foster and Polar. Furthermore, you should select a machine based on your budget so that it will fit into your cooking space even better.

Question: Why do I need a commercial blast chiller?

Answer: The best commercial blast chiller can be used for more than just cooling food down in an instant; they also help maintain flavor and color while reducing waste. If you’re not using one commercially, then we recommend looking into one now because these machines provide many benefits to catering establishments.

Question: How much does a blast chiller cost?

Answer: The best commercial blast chillers vary in price depending on the space you have available and your catering needs. Generally, these machines range from $1,500 to upwards of $12,000 for large, industrial, or walk-in units.

Question: What is the best way to safely cooling foods without a blast chiller?

Answer: Most people will cool food with ice, by placing them in an iced bath or putting them on a bed of crushed ice. Some foods, like rice, can also be cooled by running them under a cold tap, but this can both take up sink space, and waste lots of water. Using a blast chiller is a much quicker, easier, and more effective way of cooling down food quickly.

Question: How long does it take to blast freeze?

Answer: Blast freezing is the best way to preserve food in a flash. It typically only takes about one hour for most foods but can take up to three hours if the food is particularly dense.